Powder Coating Oven for Brake Shoes

Highlights of Infrared Oven Project – Powder Coating Oven

Blasdel Enterprises Infrared Powder Coating Oven reduces high oven maintenance costs for brake shoe and brake pad manufacturing company

Blasdel Enterprises was contracted by a company in the brake pad/brake shoe remanufacturing industry for the design, fabrication, and installation of a custom infrared powder coating oven system. Their current powder coating oven operation was outdated and required constant maintenance, at great cost and inconvenience to their business. After deciding to invest in a new system, the client underwent a two year research and testing period, and finally determined that the infrared ovens produced by Blasdel were the best option for their operations. To reach their goal of increased production output and cost efficiency, our medium-wave infrared oven technology was implemented. This curing oven was ideal for their epoxy powder coating method, and boasted a list of benefits including higher production capacity, a small footprint, low energy consumption, reasonable cost, and reduced maintenance.

Background

Blasdel Enterprises was contacted by a re-manufacturer of brake shoes to help the facility reduce the cost of their oven maintenance and increase production. The customer was using an epoxy powder coating as a rust inhibitor.

The operation was initially designed with seven separate remanufacturing cells. Each line contained one four-foot long shortwave oven utilizing T3 lamps with a reflective housing. Gas convection ovens were initially considered for the application, but required a large amount of floor space. The shortwave ovens have the advantage of a small footprint and reasonable energy consumption. The disadvantage is their maintenance requirements. Several months after the facility opened, the heaters began to fail. Two of the shortwave ovens had to be repaired every week which required an average of seven hours per week of labor plus the cost for parts. The cost of parts and labor combined were $26,000 per year. Downtime and its associated overtime costs contributed to the maintenance costs, as well.

The engineering team decided it was time for a new approach. Because of the past problems, the team decided that long term testing https://www.blasdel.net/blasdel-testing-lab/was required before implementing new heating technology. After two years of testing, that new approach was approved. The decision was made to install seven replacement medium-wave electric infrared ovens from Blasdel Enterprises.

Results

Blasdel Enterprises’ medium-wave infrared oven achieved all of the goals for a new curing oven including:

- Faster production capability

- Minimal floor space

- Reduced maintenance requirements

- Low energy consumption

- Reasonable capital expenditure

Advantages of using infrared for this application

Floor Space

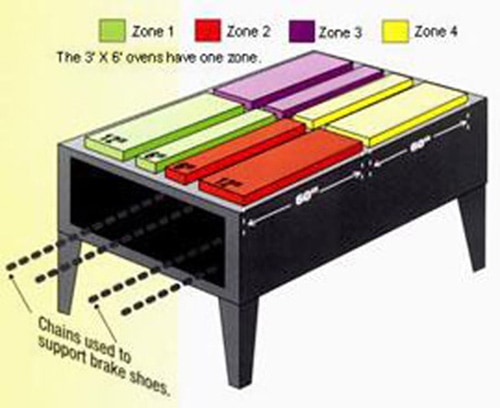

The new medium-wave infrared ovens are either 6′ or 10′ long depending on part size and weight. The shortwave infrared ovens were 4′ long. All the new ovens are 3′ wide. The shortwave ovens were operating at full power to cure the powder, whereas the new medium-wave Blasdel ovens were designed to operate at less than 50% power. The new ovens provide for future increases in line speed without adversely affecting floor space despite their length increase over the old ovens. A convection oven would have required a minimum of 50′ for the same project.

Maintenance

The shortwave infrared ovens require an average of seven hours per week of preventive maintenance. After two years of operation, no heaters have prematurely failed in the Blasdel medium-wave oven as a result of any heater problems. Several heaters were damaged by conveyor problems, but this is not related to heater design. With a typical life expectancy of 25,000 hours for Ceramic Panel Heaters, the customer will continue to operate for a long time without experiencing very many maintenance problems.

Energy Consumption

Input power rating is often viewed as the actual power usage for an electric infrared oven. In this case, the 10′ oven for producing 9″ brake shoes requires 108 kW of electric infrared energy. But, in actual operation, its energy usage is 41 kW. The energy calculation is 41 kW/hr x 6 cents per kW/hr= $2.46 per hour of operation. Based on the current production rate, it costs $.011 cent to cure five brake shoes. The energy consumption for paint and powder applications typically accounts for less that 1% of the product selling price. Our guess is that this amount is well below that 1% margin. The best part is that Ceramic Panel Heaters maintain a consistently high radiant efficiency (80%) over time.

Note: Each 18″ oven half can operate independently. This allows the heater output power to be adjusted to part weight. Because the brake shoes range in weight from 1.5 – 15 pounds, they each require different temperatures to match their curing times. The 10′ oven is used for heavier parts. The brake shoes range in size from 7″ – 12″ in radius, and there is a heavy brake shoe for trucks (15 lbs). The information relates to a 9″ brake shoe in a 10′ long oven.

Final Design

The infrared ovens were 6′ and 10′ in length, with a width of 3′. Features include individually adjustable heating zones for effective curing of various part sizes, dual chain conveyor system, and Ceramic medium wave panel heaters. Curing time is 3.6 minutes, and the ovens can handle part sizes 7″ to 12″ in diameter and 1.5 to 15 lbs. in weight. With a life expectancy of 25,000 hours, maintenance is virtually nonexistent; and each part costs 2/10 of 1 penny to gel and cure. This oven replacement project was so successful that as the customer has expanded their business they continue to choose Blasdel’s infrared oven line. For complete details about this infrared oven installation project or the other capabilities available please see the table below or contact us directly.

Contact Us

Our full line of industrial ovens includes Paint and Powder Coating Ovens, Thermoforming Oven Systems, Adhesive Curing, High Volume Air and Convection Ovens plus material handling equipment.

Established in 1982, Blasdel Enterprises is an innovative leader for custom design and fabrication of industrial ovens and material handling equipment. With equipment in the field for over 35 years, our reputation shows that we excel at all heat and motion technologies. Our full line of industrial ovens includes electric infrared ovens, gas catalytic ovens, high-velocity air or convection ovens, thermoforming ovens and other custom ovens for curing or drying. To meet your short and large production run requirements, we build batch systems as well as indexing and continuous conveyor systems. The flexibility of your oven can be enhanced through the integration of special material handling systems, independent control zones and automated loading systems. Our ovens are built to NFPA-86 Standards for Ovens and Furnaces.

We are a UL-508A rated control panel shop for the US and Canada. Also, we can enhance your system by integrating conveyors, pick and place robots and other specialty equipment.

If you have a project that needs to be assessed, contact us for testing. Blasdel Testing Lab