Custom Electric Infrared Heating Systems

Engineered Electric Infrared Oven Solutions

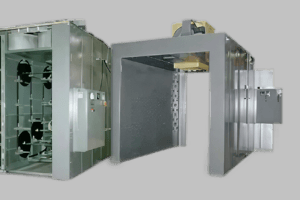

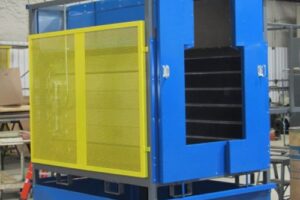

Blasdel designs and manufactures custom, infrared ovens for thermoforming, powder coating, paint curing, adhesive drying, preheating molds, moisture dry-off and other curing and drying applications.

We build custom ovens for the automotive, medical, furniture, agriculture, power and appliance industries to name a few.

The oven you buy will be designed for your part, process, space and utility ratings. We make sure that the oven you receive meets your every specification. Our ovens are used in a variety of applications and industries around the globe.

Electric Infrared Ovens Technical Advantages

- High Energy Efficiency – Radiant heat reduces wasted energy

- Zoned Temperature Control – Independent heater zones for process optimization

- Compact Design – Reduced footprint compared to convection ovens

- Scalable Configurations – Suitable for batch or inline conveyor systems

Standard Design Features

- Custom-sized electric infrared emitters matched to application thermal loads

- Multi-zone PID temperature control – Through temperature controllers or PLC. UL 508A control panel.

- Integrated exhaust safety interlocks per NFPA.

- PLC integration

Electric Infrared Ovens vs Convection Ovens

Electric infrared ovens are 4 times faster than convection ovens at heating the part, the footprint is much smaller, the warmup time is 5-7 minutes compared to 30+ minutes for convection and with little airflow, parts are not exposed to the potential contamination blowing in convection ovens.

Adding convection to an infrared oven only causes problems. The convection added by blowing air on the heaters decreases the energy efficiency of the heaters by cooling them and adds contaminates into the parts themselves

Configurations

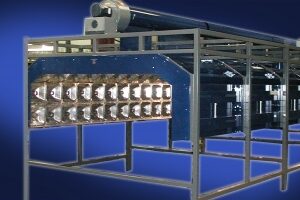

Because of our modular heaters, we can design the oven to comply with the shape of your complex parts for excellent heat coverage. And with our multiple types of emitters and the ability to build both electric infrared or gas catalytic ovens, we make sure the technology is correct for you. We have multiple test ovens to help determine the best technology and orientation for your project.

Heavy-Duty Construction & Proven Engineering

All ovens are constructed using robust steel framing designed for long-term structural integrity. Steel components are welded for strength and premium fasteners are used throughout to withstand continuous industrial operation and thermal cycling. Infrared heaters are precisely positioned at optimal distances and orientation from the product to achieve consistent, uniform heat coverage across the entire part. Each heater circuit is properly wired, tested, and safeguarded, with integrated guarding and safety features designed to meet industrial standards.

Heater Life, Efficiency & Process Control

Most infrared emitters are rated for 10,000 to 20,000 operating hours, providing long service life and reduced maintenance. Heater wattage is carefully specified so systems typically operate at 70–80% of full power, rather than running at maximum output. Operating below peak capacity reduces thermal stress on the heaters, improves energy efficiency, and ensures the system is correctly sized for the process—resulting in more stable temperatures, longer component life, and consistent production results.

Built for Long-Term Performance and Reliability

Our custom infrared and industrial ovens are engineered and built to perform reliably for decades. Every system begins with a detailed evaluation of the customer’s actual parts and process requirements. Whenever possible, we test customer materials prior to design and fabrication to validate heating performance, temperature uniformity, and process outcomes before the oven is built. This disciplined, process-first approach ensures optimal results and has helped us build a loyal base of long-term, repeat customers.

Quality Assurance

Quality assurance is built into every stage of our process. Over decades of experience, Blasdel Enterprises has carefully vetted and qualified a trusted network of suppliers to ensure our infrared heaters are manufactured to meet the exact size, output, and performance requirements of each customer’s application.

All control panels are designed and built to meet UL 508A, NFPA 86, and CAN/CSA C22.2 No. 14-2013 standards.

Each heater and heating zone is individually inspected and tested after assembly to verify proper operation and system performance.

Customers are invited for product testing during the build or prior to shipment to review their oven, ask questions, and gain a clear understanding of operation and maintenance. Once final inspections are complete, the oven is professionally crated and shipped to the customer’s facility.

Replacement Parts & Legacy Oven Support

We regularly receive calls from customers operating ovens that were built decades ago—many prior to the year 2000—and often those calls are for their first-ever replacement parts. Our equipment is designed to last, and we continue to support it long after installation.

Blasdel can also supply replacement parts for ovens manufactured by companies that are no longer in business, including Dri-Quik (CCI Thermal), Industrial Oven Company, and Ceramic Oven Company.

If your oven carries the Dial-O-Temp label, it was originally manufactured by Blasdel Enterprises, and we maintain parts support for those systems as well.