Industrial ovens and equipment by Blasdel Enterprises

– Manufacturing world-wide, high quality systems

Industrial Ovens

Oven systems built by Blasdel Enterprises include electric infrared, gas catalytic, convection, and high-volume air ovens.

To meet each customer’s unique needs, we specialize in custom design and production. Our oven systems are long-lasting and reliable. In addition, all of our ovens are built to provide years of trouble-free operation combined with excellent energy efficiency.

Oven Processes

Blasdel’s industrial ovens are used for a variety of processes.

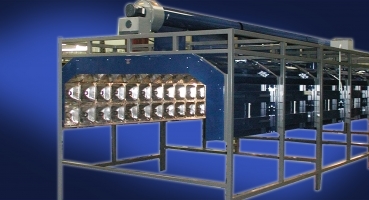

Powder Coating Ovens

Our powder coating ovens are used for many complex parts as well as flat substrates. In conjunction with a powder coating booth and customer conveyor system, our customers have been able to increase their production and cut costs. Utilizing electric infrared technology, powder coating lines that have a current convection oven can increase their production by adding a booster oven prior to the convection oven. Since electric infrared is FOUR TIMES FASTER at curing than convection, your line speed can be increased thus increasing you part output. Powder Coating Oven with Powered Width Adjustment

Liquid Curing Ovens

Liquid paint curing lines benefit from Blasdel’s infrared ovens by drying the coating more quickly than conventional ovens. With electric infrared, a positive aspect is that there is no air blowing on the part. The ensures that contaminants are not causing quality issues in you coating as a convection oven can cause. With the technology being FOUR TIMES FASTER at curing than convection, the parts cure much quicker thus increasing production. Finishing And Powder Coating Ovens

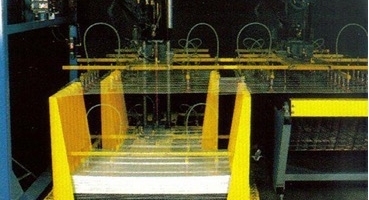

Thermoforming Ovens

Blasdel has been making thermoforming ovens for the glass mat thermoforming (GMT) industry. The electric medium wave infrared technology is ideal for this process. Our emitters are the most uniform heat in the infrared heater industry. This allows for an ideal part exiting the oven to be placed in the mold. Typically these ovens are used for automotive parts, but the versatility of this oven works well on any part that needs top and bottom heat. With a wire mesh conveyor incorporated, we ensure that the parts index smoothly. Thermoforming and Conveyor Ovens

An added bonus is an auxiliary conveyor on the exit with separate controls so the operator can unload the parts quickly. We have designed complimentary equipment with a pick and place robot for loading and an automated press loader to make these automated systems. Automatic Thermoforming Oven System Blasdel Conveyorized Oven with Automatic Press Loader

Automation

Here is a 57 second video of a finished SHUTTLE OVEN.

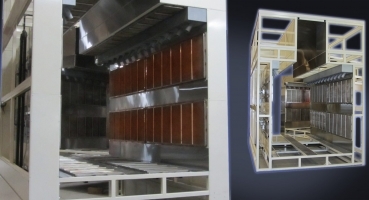

Gas Catalytic Ovens

Gas Catalytic ovens are part of our repertoire to enhance the technologies that we can provide. Some customers have the need to utilize their natural gas or LP utilities due to possible power restrictions for their location. This type of technology also works well for complex parts. With emitter temperatures reaching 1000 F, many processes can be accomplished in this type of oven. Adding an electric infrared as a booster makes this a very attractive system. Gas catalytic technology is THREE TIMES FASTER than convection systems, thus increasing part output. Gas Catalytic Oven – Heavy Equipment Paint Drying

Testing Lab

Prior to the production phase, testing is conducted at our full-scale production TESTING LAB. Process testing utilizes one or more of our industrial ovens in our facility. These ovens are all equipped with medium wave emitters. Some options are electric infrared ceramic panels, Coil-O-Rods or ceramic generators as well as gas catalytic infrared and high volume air/convection ovens. High density V-Series heaters are also available for small parts testing. Finally, we have batch industrial ovens for small production parts. Correct selection of the proper emitter for your process, eliminates potential problems in the future.

Above all, Blasdel knows that testing prior to design is imperative. It helps to ensure efficient results after installation in your facility. Potential customers may lease small test sets on a monthly basis for their own research purposes as well. We will then work with the customer to not only help them evaluate their test results as well as learn from them for a better understanding of the design needed to achieve their improved production goals. Reading the “What is Infrared Energy” technical manual linked below also helps to provide a better and more thorough understanding of how our Infrared industrial ovens will help with meeting production objectives.

Infrared Technology Resources

What makes Blasdel’s ovens different than conventional ovens? Follow this link, What-is-Infrared-Energy, for a detailed, theoretical and technical explanation about Infrared wave lengths and properties.

To purchase ceramic generators, Coil-O-Rod emitters and reflectors online, go to Order Spare Parts. For all other parts, contact us at orders@blasdel.net