Industrial thermoforming ovens and conveyor systems by Blasdel Enterprises, a proven leader in design and manufacturing.

Industrial thermoforming ovens and conveyor systems by Blasdel Enterprises are designed and manufactured for the best controlled and most uniformly heated thermoforming ovens in the industry. Since 1982, we have been the leader in supplying custom infrared thermoforming ovens to the glass mat thermoplastic (GMT) and thermoplastic industry. This same design is used for conveyor ovens that have parts horizontally conveyed.

Above all, our industrial thermoforming and conveyor ovens have precise temperature control and quick processing capabilities. This allows for flexibility when processing multiple blank sizes. The approximate cure cycle and optimal curing temperature required for manufacturing your part can be thoroughly evaluated prior to the design phase in our testing facility. https://www.blasdel.net/blasdel-testing-lab/ In our facility, we have multiple ovens with different types of emitters that will help us to determine which of those emitters performs best for your application. Our thermoforming ovens have controls using either PID (proportional-integral-controller) temperature controllers or PLC (programmable logic controller) systems which integrate with our conveyor controls.

Thermoforming Ovens

For maximum flexibility, you specify the design for zoning the heating zones to optimize your thermoforming process. For example, if you are processing multiple part sizes, heating zones can be designed to be powered down, thus reducing your power usage load. Also, zoning can be utilized to run different part sizes and configurations which help with energy efficiency and custom processing.

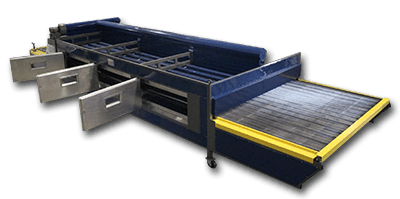

In addition, we utilize a heavy-duty non-marking stainless steel belt. To easily handle the substrate, an auxiliary exit conveyor can be added to the system for prototyping or for quick unloading of parts. We help you determine the number of indexing zones, while keeping in mind your press time. Blasdel’s thermoforming oven systems are used for heating, GMT, ABS, SMC, carbon fiber, reinforced fiberglass plastics, thermoplastics, and other substrates. Our conveyorized oven systems integrate seamlessly with your thermoforming equipment.

Auxiliary Equipment

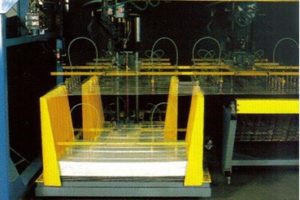

Additionally, Blasdel Enterprises designs and builds a pick and place robot for automatic loading. With your input, the loader is designed either to load the oven from the front or side according to the specifications and layout of the thermoforming system. Another key highlight is for situations where space is limited, Blasdel designs a shuttle system with the ability to load and unload from the same end. A new automated press loader can safely load your press in thermoforming systems for a more hands free process.

All Blasdel thermoforming equipment is custom designed to your needs. To ensure that you are getting the best and correct equipment, we work closely with your thermoforming processes. See some of our oven designs on YouTube.

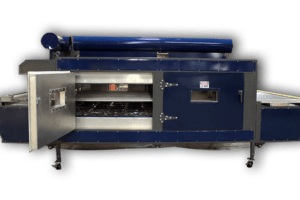

Conveyor Ovens

Our conveyor ovens work for a variety of different substrates, which is a significant factor in choosing an oven system. Since the conveyor integrates right into the framework, there is only one piece of equipment. Heating elements are arranged in the top or bottom, or in both the top and bottom, depending on your process. For example, conveyor ovens are used for headliners, gasket sealing, adhesive curing, brake pad and brake shoe powder curing, and many other processes that need to be conveyed horizontally. Most important, the all-in-one design makes installation simple. www.youtube.com/watch?v=1BOtcCEnfX0